| |

Sri Takada Industries (Malaysia) Sdn. Bhd.

No. 18, Lorong Keluli 1B,

Kawasan Perindustrian Bukit Raja Selatan,

Seksyen 7, 40000 Shah Alam, Selangor Darul Ehsan.

| Tel |

: +603-3343 5948 |

| Fax |

: +603-3343 5951 |

|

|

|

|

|

|

|

|

|

|

TAKADA TOTAL SYSTEM TAKADA TOTAL SYSTEM |

|

| |

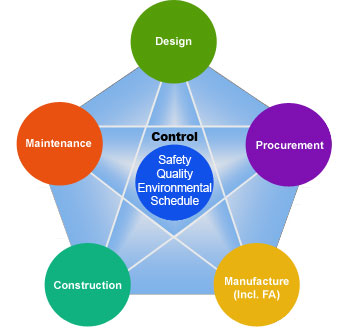

“TAKADA Total System” is the Takada Group's unique system and our business activities itself.

Through "Takada Total System", we can offer high satisfaction level by total plant engineering, from construction to maintenance. To realize customers' needs, we can execute schedule control, quality control, environmental control and safety control satisfactorily at every step in all projects handled by us.

To achieve high level, we are not only adopting quality assurance system but we also execute total coordination of all activities such as development of new technologies to meet the customer requirement, improvement of working method to increase the quality and efficiency, training and education to fulfill our technologies and skills, promotion of employees’ autonomous control activities, and so forth. |

|

DESIGN DESIGN

SRI TAKADA has various experiences of Piping design, Vessel and Tank design and Machine and Equipment design. When necessary, the expertise of Takada Japan shall be seeked. |

| |

Piping Design

We are specialist of piping design in the field of oil and gas, petrochemical, power station, etc. |

| |

| |

Vessel and Machine Design

We are specialist of machine design in the field of oil and gas, petrochemical, power station, etc |

|

|

|

PROCUREMENT PROCUREMENT

Our Procurement Division is the window of SRI TAKADA for procuring goods and also contracting with subcontractors and / or vendors.

SRI TAKADA sources for various quality and cost effective materials from local and overseas, such as :- |

|

• |

Piping materials based on engineering standards |

| |

• |

Various valves and pumps |

| |

• |

Pressure vessels, tanks and heat exchangers |

| |

• |

Compressor, fan, water cooling tower, etc |

| |

• |

Electrical and instrumentation materials |

| |

| We maintain an updated inventory control to ensure zero delay in procuring and issuance. |

|

|

|

MANUFACTURE (Incl.FA) MANUFACTURE (Incl.FA) |

| Date of Operation |

14 June 1994 |

| Location |

No. 18, Lorong Keluli 1B,

Kawasan Perindustrian Bukit Raja Selatan,

Seksyen 7, 40000 Shah Alam, Selangor.

|

| Area Size |

16,187.43 m² (174,240 ft²) |

| Clean Room |

145 m² (9.7m x 15m, Class 1,000 - 10,000) |

|

| |

| FACTORY AREA |

| ITEM |

AREA |

| Office |

1,400 |

m² |

(14.8m x 36.8m) |

| Shielded Workshop |

1,155 |

m² |

(77m x 15m) |

| Unshielded Workshop |

770 |

m² |

(77m x 10m) |

| Clean Room |

219 |

m² |

(14.6m x 15m) |

| Material Warehouse |

270 |

m² |

(18m x 154m) |

| Equipment Warehouse |

200 |

m² |

(20m x 10m) |

| Material Storage Yard (Open Area) |

355 |

m² |

(10m x 35.5m) |

| Open Storage Yard |

2,372 |

m² |

|

|

| |

| PRODUCTION CAPACITY |

| ITEM |

VOLUME PER MONTH |

| Pipe Prefabrication (Carbon Steel & Stainless Steel) |

125 Tons, 25,000 DB |

| Storage Tank |

| Carbon Steel |

: |

120 |

Tons |

| Stainless Steel |

: |

65 |

Tons |

|

|

|

|

| Total |

: |

185 |

Tons |

|

| Support & Bracket |

Carbon Steel : 20 |

Tons |

| Steel Structure |

Carbon Steel : 320 |

Tons |

| Painting |

12,800m² |

|

|

|

|

|

CONSTRUCTION CONSTRUCTION

SRI TAKADA has since its inception, involved in various Plant Construction works ranging from Oil & Gas, Petrochemical, Power Station, Fertilizer, Nonferrous Metals, Glass, Electronic, District Cooling Plants, Food Industries, etc. |

| |

|

|

Our construction activities include the following :-

• Piping and Equipment fabrication and installation

• Steel Structure fabrication and installation

• Insulation and Painting

• Electrical and Instrumentation

• Civil |

|

|

|

We will conduct plant engineering that aims at safety, high quality, matching of schedule and low cost of construction. |

|

|

|

We use the know-how of our own technology and technical skill to execute the project smoothly. |

|

|

|

We can offer our knowledge to resolve the customers problems |

|

|

MAINTENANCE SERVICE MAINTENANCE SERVICE |

Sri Takada performs a wide range of maintenance, from machinery maintenance to control system maintenance. Our maintenance capability is highly evaluated by many customers of different fields. We not only strive for the reduction of your equipment cost but also seek for general maintenance which can bring out the highest productivity of your equipment.

Sri Takada offers the optimum maintenance services, which include spot maintenance, total maintenance, daily maintenance and control maintenance. |

| |

| |

|

CUSTOMER |

SRI TAKADA |

| Equipment budget control |

|

|

| Equipment diagnosis |

|

|

| Daily Maintenance |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

| Periodical Repair |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

|

|

Spot Maintenance

This is the maintenance system to make up the shortage of existing maintenance manpower during emergency in daily maintenance of periodical repair. The maintenance can be carried out in the leadership of the customer.

The contract for spot maintenance is made whenever needed. |

| |

| |

|

CUSTOMER |

SRI TAKADA |

| Equipment budget control |

|

|

| Equipment diagnosis |

|

|

| Daily Maintenance |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

| Periodical Repair |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

|

|

Total maintenance

General equipment maintenance is performed by the customer, but after the maintenance scope is contracted, Sri Takada can provide the total maintenance and inspection of equipment for the maintenance works.

The contract is renewed every year, depending on the maintenance plan or change of contract scope. |

| |

| |

|

CUSTOMER |

SRI TAKADA |

| Equipment budget control |

|

|

| Equipment diagnosis |

|

|

| Daily Maintenance |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

| Periodical Repair |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

|

|

Daily Maintenance

General equipment maintenance is performed by the customer, but Sri Takada can provide proper engineers or technicians continuously for daily maintenance.

The achievement result is calculated based on contracted unit price which is renewed every year. |

| |

| |

|

CUSTOMER |

SRI TAKADA |

| Equipment budget control |

|

|

| Equipment diagnosis |

|

|

| Daily Maintenance |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

| Periodical Repair |

Planning |

|

|

| |

Maintenance |

|

|

| |

Information Control |

|

|

|

|

Control Maintenance

Equipment budget control is performed by the customer, but Sri Takada provides general maintenance work from maintenance planning to concrete daily maintenance.

The contact is determined by the contents of the maintenance plan. |

|

|

|

|

| |

|

|